Category

Flexible Laminated Copper High Temperature and Large Current Connector

Quick Details Place of Origin: China (Mainland) Brand Name: XINCHENG Product name: Series specification soft electrical

Basic Info.

| Model NO. | flexible laminated copper high temperature and Lar |

| Shape | Square or Tape Strip Coil Roll |

| Item | Flexible Copper Connector |

| Width | 10mm to 120mm or Customized |

| Purity | 99.9% |

| Product Keywords | Copper Strip for Transformer |

| Usage | for Flexible Copper Connector |

| Transport Package | Wooden Case |

| Specification | PIECE |

| Trademark | XINCHENG |

| Origin | China |

| HS Code | 741011000 |

| Production Capacity | 30000piece/Day |

Product Description

Quick DetailsPlace of Origin: China (Mainland) Brand Name: XINCHENG

Product name: Series specification soft electrical copper busbar connectors

Material: T2 Copper Usage: CONNECTION

Copper strips: ≥99.9%Cu Extensibility: ≥30%

use: Copper Foil Soft Connectors For Electrical Transformers Parts

type: copper flexible busbar

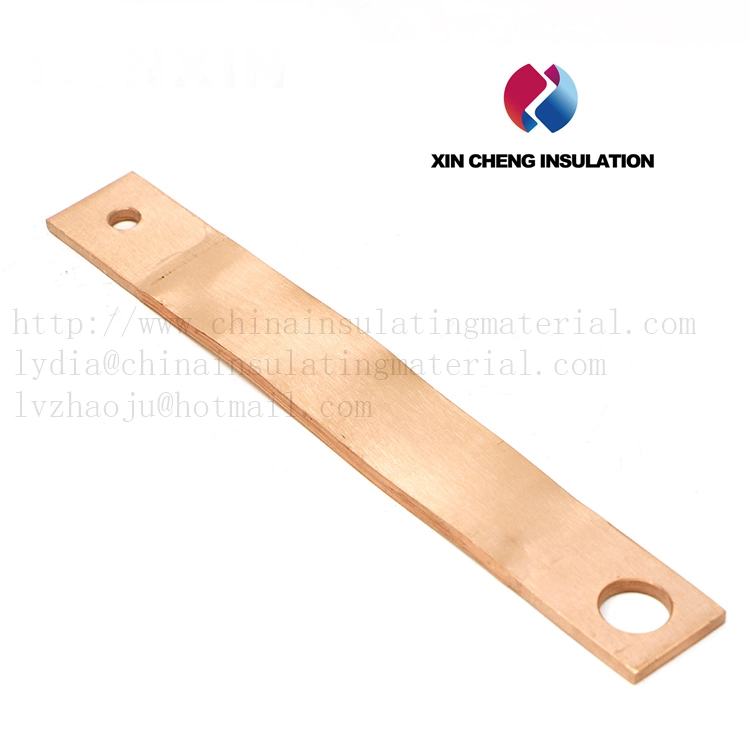

Thickness: 2mm to 10mm or customized Width: 10mm to 120mm or customized

Length: made as customer's request Shape: square or Tape Strip Coil Roll

Application: Industrial, Electric power industry spaceflight & aviation , auto-equipment and etc.

Model: copper busbar Sample: free

conductivity: > 100 IACS Tensile strength : Rm; 200N/ cm ²

Elongation: after break, > 35% Resistivity: 0.01724Ω / mm ² at 20 ºC

Item: Laminated Copper Connector

Certification: SGS; ROHS; ISO9001 Finshing: tin plating or none

Alloy Or Not: Non-alloy Temperature: high temperature Resistance

Processing: Cold press Insulation: PVC,PTE or PE heat shrink tube

Flexible Connection Busbar Product Description

Distribution power supply device is the main power supply circuit (copper row aluminum row called busbar), each branch line (row) by busbar on lead. Busbar is refers to the power supply system, electric cabinet in the total system switch and the shunt circuit switch the connection of copper row or aluminum row. Surface of insulation processing. Main function is to do for conductor.

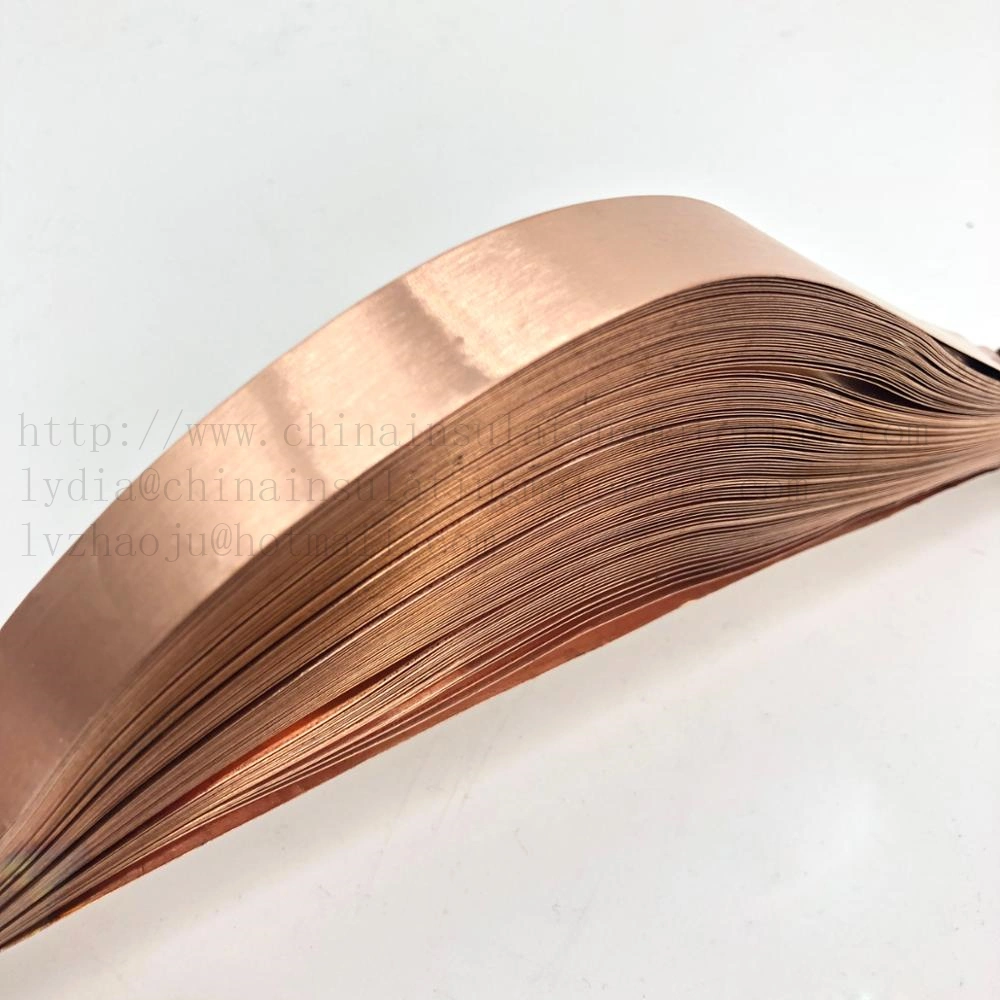

Copper braid is trough brazing the copper foil parts together. It takes silver copper base. The silver base solder and flat copper are welded together in one time by using molecular pressure welding technology welding fabrication.

Copper braid : 0.05mm to 0.3mm thick. The contact surface can be tinned or silvered according to the user's requirements. Good quality, high conductivity, high current, small resistance, durable and so on. The current is based on the customer's requirement of 1 square knitting belt, the effective loads current 4A calculation. Copper conductors with different sectional areas have different parameters. The large area can be multi-layer or set, the price depends on the current copper price and current size.

Material: high quality of copper foil

| Item | soft electrical copper busbar connectors |

| Shape: | square or Tape Strip Coil Roll |

| Material: | T2 Copper |

| Feature | Smooth finish, Durability, Flexible |

| Resistivity: | 0.01724Ω / mm ² at 20 ºC |

| Electrical conductivity | ≥4-6A/mm2 |

| Length | made as customer's request |

| Width | Width: 10mm to 120mm or customized |

Application:

Because ofthe excellent characteristic of insulated flexible busbar,it has become the first choice for electrical wiring and gradually replace the cable in the application of electrical wiring,the hard busbar of non main structure will gradually be replaced with flexible busbar.

Laminated Copper Flexibles

Laminated and Flexible Copper are developed from high conductivity based electrolytic grade copper sheets/foils. These are made using a press welding procedure where individual copper strips are fused through applying direct current as well as pressure without the need of foreign material.

The process assures minimum resistance and helps in increasing product's service life as well as bringing a reduction in downtime. Further, these also come with superior mechanical & electrical properties at high temperatures.

Laminated Copper Flexibles

Laminated and Flexible Copper are developed from high conductivity based electrolytic grade copper sheets/foils. These are made using a press welding procedure where individual copper strips are fused through applying direct current as well as pressure without the need of foreign material.

The process assures minimum resistance and helps in increasing productâ€TMs service life as well as bringing a reduction in downtime. Further, these also come with superior mechanical & electrical properties at high temperatures.

Copper Flexibles Link

Flexible Link Copper delivers maximum conductivity and minimum voltage drop without any loss of flexibility in a braid. Designed as the flexible link, these find used in spot welding machines as well as provide clients with necessary Insulation on flexible as per their specific requirements. These are also stringently tested on defined parameters before being supplied to the customers. Further, we can also offer customized solutions as demanded by the customers.

Conductor:

Insulated flexible busbar conductor use T2 soft state copper belt, the soft state can devide to bare copper and tin plated copper

Insulation layer:

Flexible insulating busbar of insulating layer has specialpolyvinyl chloride (PVC) and thermoplastic elastomer (TPE) of two kinds of materials. The characteristics of TPE with low smoke and no halogen.

Production standards:

Flexible insulating busbar don't have a special standardin the world, The United States borrow UL758 electronic line standards for production certification,China's enterprises refer to GB/T5023 insulation cable standard and UL758 electronic line standard.

Technology:

Adopt pressure welding, brazing, butt-welding and other mature technologies manufacturing.

Advantages: The products have good flexibility,heat dissipation,resistance to bending, strong conductivity, convenient to install,in addition, the flattening terminal and bright overall ensure the beautiful outlook of the products.

1. Excellent electrical conductivity.

2. High bonding strength.

3. Available for bending, drilling, stamping etc.

4. Pure T2 copper

5.Easy processing and forming

6.High load flow

7.Easy installation

8. The T2 copper is unable to be broken after 150 times bending test.

Packaging & Delivery

Packaging Details:

Inner packing : plastic bag /inner box

Outer Packing : export carton with pallets/ According to customers' requirement

Delivery Time: About 7-15 days.

Our Services

1. We are professional manufacturer, We are manufacturers of bus bar with automatic machines, professional development, production and inspection teams. OEM / ODM is welcome.

2. We are factory has passed ISO9001 and ISO14001 system certification,and has established IATF16949 quality management system.

3. We are factory with competitive price and free sample.

4. Enough stock to meet fast delivery.

5. 2 year's quality guarantee.

6. Sale's service team will solve problems after customer receive goods.

7. Form E, C/O is available.

8.we also can provide the Copper Flexibles Braid, Laminated Copper Flexibles, Copper Flexibles Link, Copper Flexible Bus Bars, copper braid wire, copper flexible connector, laminated copper, ground copper rod, copper wire lug, etc.

FAQ

1. Q: Are you factory or trading company?

A: We are factory.

2. Q: Where is your factory located?

A: We are located in the TIANJIN city, near the BEIJING city , China.

3. Q: Can I get sample before making order?

A: We can send you free samples if you tell us the model and size you need, or you send us your drawing.

4. Q: Do you accept small order or trial order?

A: Small order and trial order are acceptable.

5. Q: How long can I get a sample?

A: we have sanples in stock, we can send it in one day.

6. Q: How do you inspect goods?

A: We have inspection department. All goods will be inspected before packing.

7. Q: What's your payment term?

A: For small order, we suggest 100% before production to save time and bank charge. For bulk order, 30%TT deposit 70%TT before delivery.

Please Contact Us

Miss: lydia

Mob: 86-13752439076 Fax: 86-22-60863016

http://chinainsulation.en.made-in-china.com